Lead Time for Amazon Sellers: What It Is, Why It Matters, and How to Improve It

If you sell on Amazon, lead time quietly decides how much you sell and how much cash you tie up. This guide explains what lead time includes, why it drives ranking and profit, and the moves that make it shorter.

Jump to the section you need:

Lead Time 101

Lead time is one of those simple concepts that can make or break your Amazon business. In plain terms, it's the total time from when you place an order with your supplier to when those products are ready for customers to buy on Amazon. That's it. Production, shipping, customs, Amazon processing – the whole journey.

Here's a quick example to show what we mean: Let's say you sell wireless earbuds and you place an order with your manufacturer in Shenzhen. They need 10 days to produce your batch. Then you ship via ocean freight, which takes about 35 days. Add a week for customs clearance and trucking to the fulfillment center, plus another 4-7 days for Amazon to receive and check in your inventory. You're looking at roughly 8 weeks from "submit purchase order" to "available for sale." That's your lead time, and it's a number you need to know cold.

Let's break down what goes into that timeline:

- Production Time: How long your supplier needs to manufacture your order. This could be a few days if they have everything ready to go, or several weeks if they're making custom products or sourcing special materials.

- Shipping Time: The journey from your supplier to Amazon. Ocean freight typically runs 25-45 days for Asia to the US, while air freight might be 5-10 days if you're willing to pay for speed.

- Customs and Transit: Time for your shipment to clear customs and get trucked inland. Customs processing in the US usually takes 5-7 days, but it can stretch to two weeks if things get backed up.

- Amazon FBA Check-in: Once your shipment arrives at the fulfillment center, Amazon needs time to receive and process it. Normal times might be 3-5 days, but during Q4 holiday madness, you could be waiting 7-14 days or more.

All these pieces stack up to create your total lead time. And if any one piece runs long – maybe customs gets backed up or your factory hits a snag – your whole timeline extends. Now let's talk about why this matters so much.

Why Lead Time Matters

Lead time might sound like boring logistics stuff, but it actually impacts nearly every part of running a profitable Amazon business. Master your lead time and you'll have happier customers, better cash flow, and fewer middle-of-the-night panic attacks about running out of stock.

1. The Ranking Flywheel: Why Thin Inventory Kills Your Organic Visibility

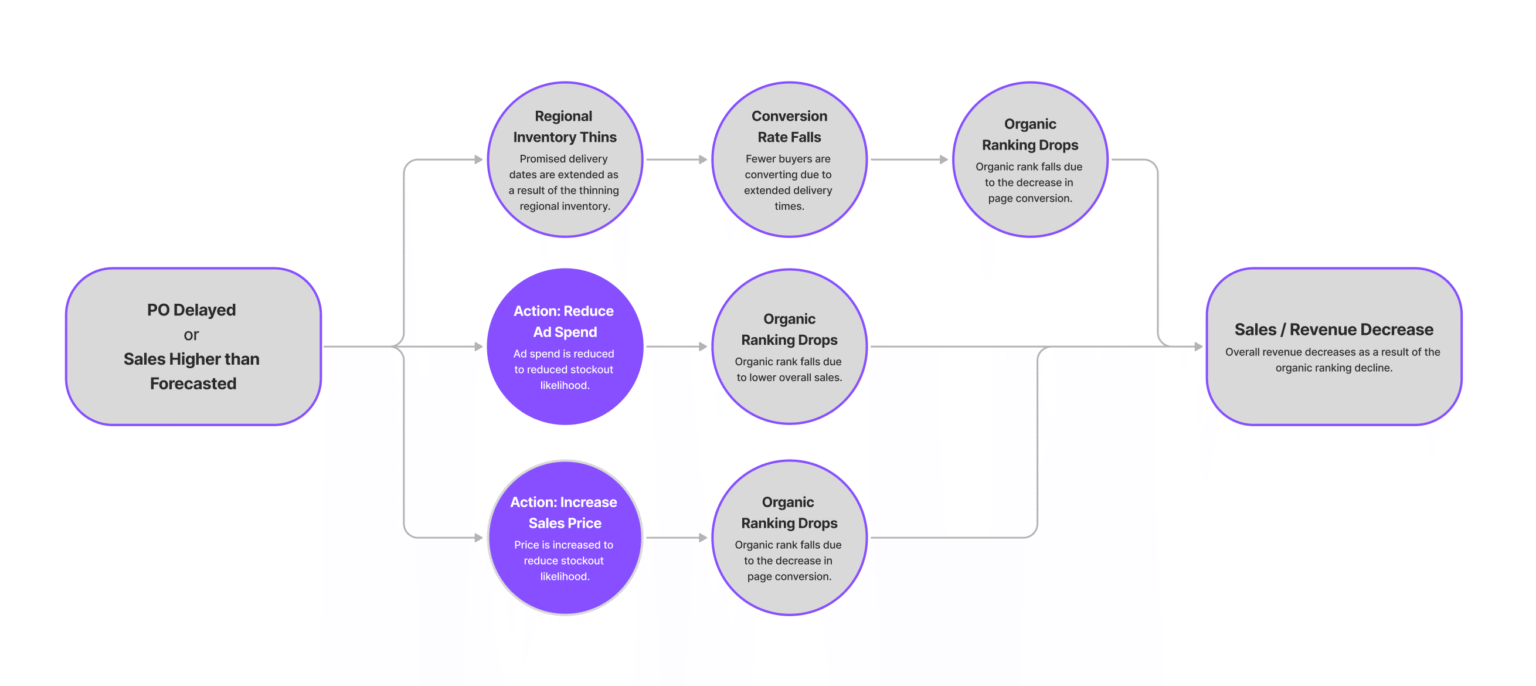

Most sellers think stockouts are bad because you miss sales while you're at zero. That's true, but here's the sneaky part that costs you even more: your ranking can start tanking before you fully run out.

Here's how the death spiral works:

Inventory thins. You still have stock, but it's concentrated in fewer fulfillment centers across the country.

Delivery promises get slower. Amazon shows longer delivery estimates to shoppers who are far from your remaining inventory. Even a one or two day slip hurts conversion badly.

Conversion falls. Fewer buyers click "Add to Cart" when they see a slower delivery promise. Why would they when your competitor's similar product arrives two days faster?

Organic ranking drops. Amazon's search algorithm absolutely loves listings with strong sales velocity and conversion rates. When your conversion dips, your rank slips, your sessions fall, and your velocity slows down even more.

That loop doesn't require a full stockout to start destroying your business. A thin inventory position can quietly extend delivery times for large chunks of the country, reduce your conversion rate, and push your organic rank down while your Seller Central still shows "in stock." By the time you restock after a long lead time, you might find yourself on page 3 instead of page 1, and clawing your way back up takes weeks or months.

If you're a reseller, there's an added wrinkle: running out of stock can also hurt your ability to win the Buy Box, which is critical for making sales. But for most private label sellers, the real killer is that organic ranking drop. You worked hard to get to the top of search results, and a lead time miscalculation can undo months of optimization and advertising spend.

Bottom line: Shorter, more reliable lead times help you maintain consistent inventory depth across Amazon's network, which keeps delivery promises fast, conversion high, and your organic rank strong.

2. Customer Satisfaction Impacted by Delivery Speed

Today's customers expect their stuff fast. When you sell FBA, Amazon's Prime shipping keeps customers happy – but only if you actually have inventory available for them to buy. If your inventory management is shaky because of long lead times, you risk showing slower delivery estimates that drive customers straight to your competitors.

The numbers don't lie. Studies show that 69% of shoppers are less likely to buy from a retailer again if their delivery gets delayed, and 53% have straight-up canceled orders because shipping was too slow. While FBA handles the actual delivery, your lead time management determines whether you have stock positioned where Amazon needs it to promise fast delivery.

On the flip side, when you consistently keep inventory in stock with good distribution across fulfillment centers, Amazon can promise faster delivery to more customers. That builds trust, drives better reviews, and creates repeat customers who know they can count on you.

3. Cash Flow – Your Money Is Sitting in Shipping Containers

Long lead times aren't just about time. They're about your money being locked up and unavailable.

Think about it this way: If your lead time is 10 weeks, that means you're paying your supplier and then waiting two and a half months before you can start selling those units and getting your cash back. During those 10 weeks, that money is just... gone. You can't use it to buy more inventory, run ads, or test new products. It's sitting on a boat or in a warehouse doing nothing for you.

The longer your lead time, the more capital you need tied up in inventory at any given moment. You've got products in production, products in transit, products in customs, and products waiting to be received at Amazon. All of that is money you've spent but can't access.

Contrast that with a shorter lead time. If you can cut your lead time to 5 weeks instead of 10, you free up cash flow dramatically. You can order smaller batches more frequently, which means less money locked in inventory at once. You turn that inventory into sales faster, get your money back faster, and can reinvest it faster. This is why inventory turnover matters so much – the faster you can move from purchase to sale, the more efficiently your capital works for you.

Plus, while your products are in transit and storage, you're often paying storage fees, insurance, and other carrying costs. And there's always the risk that by the time your products finally arrive, market demand has shifted or a competitor has launched something better.

4. Less Safety Stock, Lower Storage Fees

When your lead time is long or unpredictable, you're forced to keep extra safety stock on hand. Safety stock is your buffer – the extra inventory you hold just in case something goes wrong with your next order.

If you know your supplier might take 8 weeks or might take 12 weeks (and you never know which), you'll probably order extra units or keep more inventory in FBA just to be safe. That might prevent stockouts, but it costs you in storage fees and increases your risk if demand suddenly drops or if you need to liquidate excess inventory.

Here's the good news: when you shorten your lead time and make it more predictable, you can confidently reduce your safety stock. You don't need as much buffer because you know you can restock quickly if needed. That means lower storage costs at Amazon's warehouses and less capital tied up in "just in case" inventory. You can run leaner and more profitably.

5. Speed Equals Competitive Advantage

The Amazon marketplace moves fast. Really fast. Trends pop up overnight. Competitors launch improved versions of products. Demand can spike unexpectedly.

Sellers with short lead times can react much quicker to all of this. If you can restock in 4 weeks and your competitor needs 8 weeks, you have a massive agility advantage. You can test new products in smaller batches, respond to sales spikes, or recover from an unexpected sellout while your competitor is still waiting for their container ship to arrive.

Let's say two sellers offer similar fitness equipment. Seller A has a 5-week lead time. Seller B has a 10-week lead time. When demand surges after New Year's, Seller A can restock twice in the time it takes Seller B to restock once. Seller A stays in stock with fast delivery promises, maintains high conversion and organic rank, and captures more of the market. Seller B runs out, loses ranking, and spends months trying to recover.

Being known for always having stock and fast turnaround is a real competitive edge. It helps you win more sales, justify premium pricing, and build customer loyalty. Even massive companies have proven this – Nike cut their production lead times by 40% using just-in-time strategies and saw a 20% productivity boost as a result.

In short, lead time touches everything – your cash, your rankings, your sales velocity, and your ability to compete. It's not just about speed, but about the predictability of your entire supply chain. If you can shorten your lead time or just make it more reliable, you'll see benefits across your entire business.

Is this article helpful? It could've been in your inbox.

Don’t miss out on new articles. Subscribe to our newsletter and get your monthly dose of Amazon FBA business insights.

Error: Contact form not found.

How to Reduce Your Lead Time

Reducing lead time might seem daunting, but there are practical steps you can take right now. The goal isn't to rush everything recklessly – it's to make your supply chain efficient and predictable. Even implementing one or two of these strategies can make a noticeable difference.

Optimize Supplier Production

Start at the source. Have an honest conversation with your supplier about their production schedule. Can they start production earlier if you give them better forecasts? Can they source raw materials faster? Sometimes paying a bit extra for priority handling or premium materials can shave weeks off manufacturing time.

If your current supplier consistently misses deadlines, it might be time to find a backup supplier or even switch entirely. One seller we know was constantly dealing with 8-week production times from their overseas manufacturer. They found a supplier in Mexico who could produce the same product in 3 weeks. Not only did this cut their lead time in half, but it also reduced shipping time and simplified customs since it was all within North America. Their conversion rate jumped 28% because they could keep inventory levels more consistent, leading to faster delivery promises.

Building a strong relationship with your supplier helps too. A supplier who values your business will prioritize your orders, communicate proactively about potential delays, and work with you to find solutions. If you're a significant customer, negotiate for better terms – shorter production windows, priority during peak seasons, or the ability to split orders for faster partial shipments.

Streamline Shipping and Freight

The transit phase is often the longest chunk of your lead time, especially if you're importing from Asia. But this is also where you have options.

First, choose your shipping method strategically. Ocean freight is cheap but slow (4-6 weeks). Air freight is fast but expensive (5-10 days). Many smart sellers use a hybrid approach: ship 80% by ocean to save money, and ship 20% by air to bridge any inventory gaps. If you're facing a potential stockout, it's often worth the extra cost to air freight a portion of your order while the bulk comes by sea.

Second, work with a reliable freight forwarder who knows Amazon's requirements inside and out. A good freight partner will ensure your paperwork is perfect to avoid customs delays and will coordinate delivery appointments with Amazon's fulfillment centers. They'll also give you realistic transit time estimates and help you navigate changing global shipping conditions.

Don't forget about timing. Avoid shipping during peak seasons if possible. Trying to land a shipment in late September or October when everyone is ramping up for Q4? Good luck. Ports get congested, customs gets backed up, and Amazon's receiving slows to a crawl. Ship earlier to avoid the rush.

For domestic transit after customs, consider using Amazon's partnered carriers or their Direct Import programs if you're eligible. These can sometimes cut days off your inbound timeline by streamlining the path from port to fulfillment center.

Speed Up Amazon Receiving

Once your shipment arrives at Amazon's warehouse, you want it available for sale ASAP. While Amazon's receiving process is mostly out of your control, you can avoid unnecessary delays.

Follow FBA requirements perfectly. That means proper labeling on every box, accurate box content information, correct FNSKU barcodes, and following Amazon's pallet requirements if you're sending pallets. Screw this up and Amazon will set your inventory aside for manual processing, adding days or weeks to your receiving time.

Ship inventory earlier than you think you need to for peak seasons. If you're gearing up for Black Friday, don't wait until October to ship. Amazon's Q4 receiving can take 7-14 days or more. Many experienced sellers have inventory arriving in September or early October to avoid the holiday bottleneck.

Consider using a third-party logistics (3PL) warehouse as a staging area. A 3PL can store excess inventory domestically and send smaller, more frequent shipments into Amazon. This accomplishes two things: smaller shipments often get checked in faster, and you always have backup stock ready to send in. While this adds a step, it can effectively shorten your replenishment lead time because you're not waiting on one giant shipment that might get delayed.

Better Demand Planning and Inventory Management

Perhaps the most powerful way to reduce the impact of lead time is to plan around it intelligently.

Start by accurately calculating your current lead time from order placement to FBA availability. With that number, schedule your reorders with plenty of cushion. If your lead time is 60 days and you want a 30-day safety buffer, you need to reorder at least 90 days before you expect to run out.

Use the reorder point formula as a guide: Reorder Point = (Average Daily Sales × Lead Time) + Safety Stock. Track your sales velocity, factor in your full lead time, and set reorder alerts accordingly.

Keep an eye on seasonality and external factors. If you source from China, Chinese New Year can add 2-3 weeks to your lead time when factories shut down. Mark these dates on your calendar and order early. If you sell seasonal products, remember that your supplier might need extra lead time when they're busiest.

You can also negotiate better payment terms with your supplier to ease cash flow pressure. If you currently pay 100% upfront, try negotiating for 30/70 or even payment upon delivery. This doesn't reduce lead time, but it reduces the financial pain of having cash tied up for weeks or months.

Forecast realistically. Don't assume the shortest possible lead time. Plan for delays – a port strike, unexpected sales surge, factory issues, etc. Use data from past orders and seasonal patterns to adjust your reorder timing and quantities. If you know Q4 sales are typically double Q2, factor that into your planning.

Good planning won't reduce the actual days it takes to manufacture and move goods, but it ensures those days don't catch you by surprise.

Lead Time Reduction Checklist

Here's a quick reference you can use when evaluating and improving your lead time:

- Break Down Your Current Lead Time: Document each stage – production, transit, customs, FBA check-in – and how long each typically takes. This shows you where the biggest delays happen.

- Buffer Your Reorder Point: Calculate when to reorder using your lead time plus a safety margin. Order well before you're low on stock so delays won't cause stockouts.

- Communicate with Suppliers: Ask if they can reduce production time or if they see any upcoming delays. Maintain good relationships so you're first to know about issues. Research backup suppliers for critical components.

- Optimize Shipping Decisions: For each shipment, choose the best transit method. Use faster shipping for urgent restocks and slower methods when time allows. Always ensure paperwork is complete to prevent customs holdups.

- Prep Shipments for Smooth FBA Receiving: Follow Amazon's packing and labeling requirements exactly. Send inventory before major sales spikes or peak seasons, not during them.

- Consider Inventory Staging: If your lead time is very long or FBA receiving is slow, use a 3PL to hold inventory domestically. Send smaller, more frequent shipments to Amazon from there.

- Review and Repeat: Periodically revisit your lead time and these steps. As your business grows, you'll be able to negotiate better terms and find new efficiencies. Track your results so you understand what's working.

Lead time management might not be the most exciting part of selling on Amazon, but it's one of those behind-the-scenes factors that separates amateurs from pros. With the tips in this guide, you're better equipped to make lead time work for you instead of against you. Keep your inventory flowing, your customers happy, and your cash free to grow your business.

Is this article helpful? It could've been in your inbox.

Don’t miss out on new articles. Subscribe to our newsletter and get your monthly dose of Amazon FBA business insights.

Error: Contact form not found.